What does Lead Time Measure?

What is “lead time” ?

In your production, service, or business process, you have defined internal steps or procedures separate from the active working time. E.g., the accumulation of tasks in the queue waiting for the availability of the workforce, or the green light for the next step of the work, for a test result and approvals, delivery dates, etc. These steps allow you to manage the process the best you can and ensure the required product quality while, at the same time, respecting the needs and pace of the team delivering it.

However, your clients usually know nothing about the intricacies of your internal processes and other jobs you’re processing. What matters to them is the time between their order placement and delivery. That is the lead time. It is what the client sees as your processing speed, and therefore it would be best to make this time as short as possible.

Why does the lead time measurement matter?

The lead time is, in most cases, the only time measurement with which your clients are concerned. Being able to deliver an order quickly, or at the least, having the ability to forecast the delivery accurately, will often be one of the decisive factors in a client choosing you over the competition. And, keeping promises you make to your clients will further help your relationship and reputation.

Furthermore, by cleverly estimating the lead time of different projects, you can better plan your team’s work and make the best use of their availability. That means a more reliable completion prognosis with higher throughput, hence better profits and less wasteful downtime.

When does the lead time start and finish?

The lead time is the most straightforward measurement to calculate within the Lean management framework. It’s the entire period between receiving all requirements or the order for the product from the client and the moment you deliver it for their use.

Examples

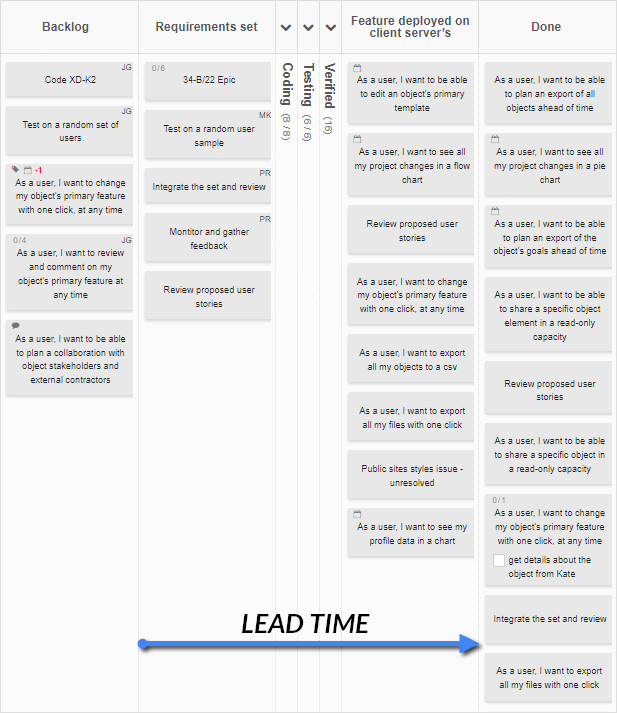

For a simple software development process, the lead time is the number of days (or hours, if you’re that good!) between a task settling into the “Requirements set” column and the “Feature deployed on client server’s” stage. So, the value includes everything: both the waiting and the doing steps, all tests, and the time it took to implement the ready and tested code for the client’s use.

And in a manufacturing scenario, the lead time will be the sum of:

- the time you need to wait for all parts of the product to arrive from your suppliers,

- together with the time it takes you to run the parts through all production steps and to test the final item,

- with the addition of time required to deliver the item to the client.

How to shorten your process’ lead time?

First, consider making things easier for yourself, and use automated systems that measure your process’ lead times. That will give you a baseline to compare to after you’ve started to make improvements.

Step 1: Improve active work stages’ efficiency

While this is the most common-sense solution to minimizing lead time, perhaps surprisingly, the production time is not always the highest value in the total lead time. Still, you want the production stage of the process to be as efficient as possible, regardless of everything else.

To improve the productivity of the working stages, consider these methods:

- Applying work-in-progress limits to the process steps.

WIP limits help the team focus on one task at a time and force them to finish started jobs before engaging with another. - Paying attention to bottlenecks identification and elimination.

Set process stages becoming blocked with items in numbers much higher than those in any other indicates a problem at that process step. It may be that not enough people work there, they’re not sufficiently skilled, or the tasks are arriving incomplete or impossible to understand. Either way, the bottlenecks slow down the entire system and cause inefficiency and unevenness in the processing, so suboptimal use of all other resources. - Using a transparent pull system.

A Kanban or Scrum system can inform or even alert consecutive stages’ teams of the need to act - whether the action will be to restock an element, pick up more tasks or prepare delivery. Pull systems, unlike push systems, only allow employees to “pull” new work when the previous tasks are done. The approach supports better concentration and minimizes stress. Complete transparency in the system promotes better coordination between stages and job ownership among the team.

In a strict manufacturing scenario, a pull system might also take the form of a finished products store, from which new client orders get realized (pulled), driving both preproduction and production times down to nothing.

Step 2: Minimize waste

Just as you’d do good to streamline the active work stages as much as possible, it’s just as crucial to reduce any unnecessary steps and actions, to minimize waste.

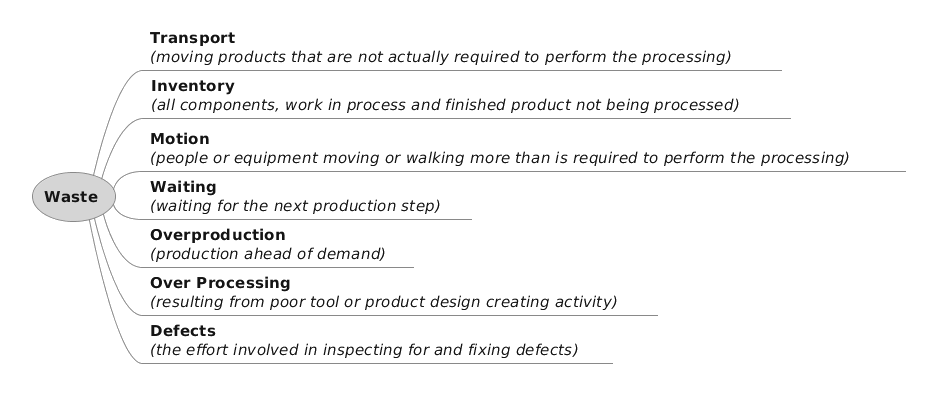

Process throughput, the amount of product it produces in a given time, directly impacts the lead time. To increase throughput, you’d need to introduce more people or machines, or better-skilled people and higher performance equipment, to speed up the processing of the ordered work at the busiest process stages. Half-done items waiting for processing are a form of muda (waste). For a fuller picture of what waste to reduce and avoid, note all types of muda identified by Lean practitioners in the image below. And here you can find the recommended ways of addressing each of them.

Seven kinds of waste (Muda)

Seven kinds of waste (Muda)

The just-in-time production concept is one of the pillars of the Toyota Production System. Imagine a company producing the required product at the exact time when it’s needed, in the precisely ordered amount. It would mean near-zero levels of waste in time and material. That is the goal that pull systems and WIP limits help to achieve!

Step 3: Apply Heijunka to supply and production

Since not only your production pace impacts the lead time, it would pay to work on as good a relationship with your suppliers as possible. The aim would be to match your restocking patterns to your clients’ ordering patterns, letting you level out the supply chain with your needs. If not possible, the next best thing would be to allow flexibility in how your parts are delivered: arranging short-term arrivals and extended payment terms to help you get your hands on what you need regardless of other factors.

Heijunka is a Lean management term describing process flow leveling: making it as even and predictable as possible to allow a sustainable pace of work for the team and a reliable way of foreseeing product delivery times to clients. In other words, it addresses the unevenness (mura) within the process.

Step 4: Reduce the waiting stages time

By applying WIP limits to the queuing, non-active process stages, or by employing cross-skilled team members, who will be able to change roles based on current demand, you can decrease the time that jobs are just sitting, waiting for another step. Thanks to this, you will minimize the gap between the lead time: total time from order to delivery – and the cycle time: the time you’re actively working on the order.

Did you know?

Kanban Tool® visual boards can give you real-time values for each task’s lead time. They also automatically generate a Lead & Cycle Time metric, with which you can track how long an item takes to move from one stage to another. Test it with your team for free!

The length of the idle queues in the system matters for your total lead time, but it also impacts the coordination of work between different teams. You want the system to have only as little slack as reasonably necessary, as otherwise, you will get periods when teams are standing around with nothing to do.

Step 5: Automate all those jobs that you can

Have all routine tasks, status updates - and the notifications that they should cause - become automatic. In production scenarios especially, a good idea may be automating materials ordering - so that new batches are requested once the stock goes down to a set level. It’s a clever way to cut down waiting times and delays.

Frequent, repeated measurements of your process lead time will help you estimate how you respond to client demands. And although product quality is likely to be the highest value in a production process, the speed of delivery will always be right behind it. Try adopting Lean management to your operations to achieve the highly desirable marriage of high-value product delivery at a high yet sustainable pace.