Lean Methodology

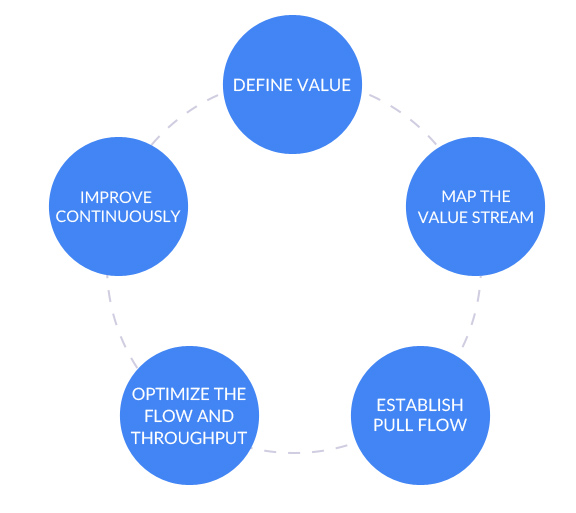

Lean methodology balances the elimination of waste with increasing productivity. It proposes achieving this by continuously improving all facets of the process, respecting the employees, and creating value for the customer with every process change.

Lean is an umbrella term for various waste-reducing techniques, one of which is Kanban.

Though originating on the manufacturing scene, Lean can also adapt to non-industrial, knowledge-based systems, bringing measurable and satisfying results. The goals of the Lean methodology are:

- Limiting waste

- Putting people first, not processes

- Delivering fast and often

- Applying the customer’s point of view when designing a product

- Introducing improvements across the board, not in select teams only

- Always taking improvement opportunities.

Continuous improvement, or Kaizen, is a distinctive aspect of Lean. Informed changes apply through engaging each employee in observing the process, finding flaws, waste, and analyzing them along with other data.

Instead of agreeing on a once and forever set process, Lean methodology asks us to stay open to improvement opportunities.