What is Root Cause Analysis?

Root cause analysis (RCA) is a systematic, scientific approach to determining the principal cause of a problem. Once the root of a problem is known, it’s possible to find a truly effective solution - one that will stop the problem from happening again, as opposed to merely treating its current effects.

Identifying the real cause of a problem matters. By fixing issues other than the root cause, companies invariably produce more waste, which is against Lean management principles, and nothing that any company needs.

Root cause analysis links closely to Saikichi Toyoda, the father of the 5 Whys technique, used to find the source of a problem. It is fitting to know that the first Lean company: Toyota, started by Toyoda’s son, was founded to solve problems stemming from using a manual loom.

But solving problems not only creates new business opportunities. First and foremost, it helps companies to improve and create more value for their clients. The challenge is that, since countless types of problems can occur in any process, there is no one type of solution or even one way of finding the solution that works for everyone, every time. Thankfully though, A3 thinking, 5 Whys, Ishikawa diagram, Failure Mode and Effect Analysis (FMEA), and SIPOC are just a few of the Lean tools categorized under root cause analysis.

Why turn to root cause analysis?

Typical reasons for applying RCA are a failure to deliver service/product, receiving negative feedback from clients, experiencing a sudden drop in productivity, or unplanned downtime. Root cause analysis usually takes a significant amount of time to perform, making some managers hesitant to use it. The following are a few reasons why applying this approach is beneficial, despite its time consumption:

- Address the actual problem.

If companies rush in to find solutions without pinpointing the source of a problem, it leads to an increase in waste and a potential creation of new issues. - Unify the team.

Investigating a problem root cause can foster unity between team members, often holding different opinions on why a problem occurs. Through qualitative and quantitative data, RCA should show the real reasons why an issue or defect presents, helping to establish objective buy-in from all stakeholders. - Ensure that the solution is maintained.

John Foster Dulles, the Secretary of State under Eisenhower, said: “The measure of success is not whether you have a tough problem to deal with, but whether it is the same problem you had last year”. RCA allows you to involve the team in determining the cause of a problem, and therefore lets you ensure that the obstacle does not reappear. It helps to develop solution ownership. - Facilitate deeper communication and learning.

Retrospectives are an efficient means of gathering information for root cause analysis. Having the team tackle a persistent problem will bring them together and may lead to improvements outside the scope of the initial dilemma.

Did you know?

A simple way of bringing a team together to solve process issues is to organize their collaboration on an online Kanban Tool® board. Making the process transparent works towards informing and empowering the team in collaborative problem-solving. Try it out!

How to perform a root cause analysis?

One of the simplest ways to do an RCA is with 5 Whys. The method asks a team to state the problem and ask “why?” questions until the answer reveals the root cause. Please view this article to see an example of its application.

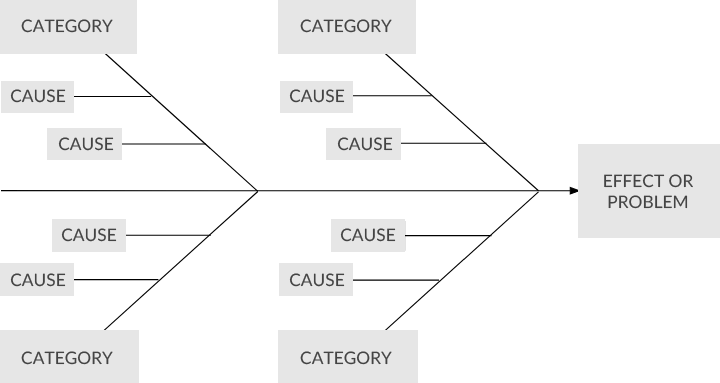

You can also use a fishbone diagram - to help visualize the problem categories, often following the 5M model: man, machine, material, method, maintenance, together with their potential causes, for subsequent analysis with 5 Whys.

Step 1: Name the problematic effect

Clearly describe how the main undesired effect presents and what parts of the process it affects. It will form the head of the fish on the diagram. Data is vital. Think of how you can quantitatively express the undesired effect and the desired state.

Step 2: Gather data

Now list all the suspected reasons for the problem to be occurring. It’s good to start with categories, e.g., people, processes, equipment, measurement, management, suppliers, skills, environment, etc., or the 5M mentioned above. The fishbones connected to the head represent the categories. At this stage, you should also gauge the timeline: when was the process last functioning correctly, without this unwanted effect?

It can often be the most challenging step - without sufficient data, it will be hard to tell if the identified root cause is valid. Data will also help you establish the baseline with which to quantify your improvements later. Be sure to speak to all workers that experience the problem and gather the available process/material information. If an analysis of the Fishbone Diagram that you’re able to build is not giving you the evident root cause, then at least it should help you define the areas that need further investigation before you take another shot at the RCA.

Step 3: Define possible causes

Link all possible and known problem causes under the appropriate category. Look out for any sequences of events that make the problem present, and take a moment to analyze if any specific conditions coexist with the issue. Also, think of whether the problem creates further complications within the process. If so, they need noting down too. At the end of the session, you should have a diagram that resembles the scheme below.

Step 4: Identify the root cause

Thanks to the cause and effect graph, you can now select the top couple of reasons and conduct a 5 Whys exercise on them, methodically reaching the heart of the problem. It allows for a deep understanding of the nature of the difficulty, the lack of which is very often the reason the issue exists in the first place!

Step 5: Implement a solution

With access to your complete analysis of the problem, you can design a solution and follow its implementation. You will need to choose a method of solving the difficulty which will have as little impact on the ongoing production as possible. It will also need to offer a way to measure its success and introduce the smallest amount of new risk.

RCA - not only for solving problems!

Root cause analysis is a convenient exercise not only when dealing with problems. Often, an issue will present as a business improvement opportunity, and an RCA can certainly help identify the key possible areas of change.

Examples

- Dealing with staffing issues - an RCA of those can clearly show flaws in staff performance and highlight the required revisions.

- Investigating a new marketing opportunity - using the 5 Whys will help stakeholders understand the true nature and potential of the opportunity.

- Brainstorming a new product iteration - an analysis of the problems the existing product/service is presenting gives direct clues as to what needs changing.

You will know that you have found the correct solution to your problem if, at the end of the root cause analysis, you can make it disappear and reappear by removing and reinstating the cause. This validation is crucial. For example, Six Sigma practitioners focus intensely on proving the correct identification of a root cause before moving on to implementing a solution.