What is Process Throughput?

Process throughput measures how much of a completed product a process delivers in a given period.

In traditional Kanban systems, it’s the number of completed cards per day, week, or a given iteration time. Process throughput, aka flow rate, relates directly to the cycle time: the time it takes to complete a process. It’s one of the Lean and Lean Six Sigma metrics used to evaluate process performance.

It is important to note that process throughput deals only with completed items - in the form that the customer accepts them. Work in progress is not taken into account.

What does process throughput help to determine?

- How long it will take to fulfill an order

- What are the costs of the process (throughput accounting)

- Staffing & production capacity and requirements

- The process efficiency

The above 4 factors affect how successful your business will be, making process throughput one of the best Lean ways to measure efficiency and profitability. Process throughput, work in progress, and the cycle time all play a role in the Little’s law, centered around the predictability of flow within a queue.

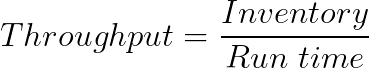

where:

- inventory is the number of items in the process

- run time is the time it takes for the inventory to be processed.

While cycle time measures how responsive to new orders a process is, the throughput measurement indicates the average processing speed. Before you work on improving the process throughput, first, establish a baseline of the processing time and complexity, and compare them to the industry’s benchmarks. Doing this will let you know if your change efforts have the expected results.

How is process throughput calculated?

There are a few different ways to calculate process throughput:

- Conducting a physical count of the number of items that a process completes in a given period. Of course, you need to average it to get a reliable indication of the metric.

- Pulling a throughput report from an electronic Kanban system

- Dividing the number of items in the inventory by the time they take to get completed.

Did you know?

Kanban Tool® incorporates a clever way of measuring your process throughput. With the Lead & Cycle Time diagram, you can compare the time spent actively working with the time the items have spent in the process as a whole. Try this and other automated metrics for yourself!

Whichever calculation you use, make sure that it also considers the following:

- the number of items ordered

The difference between the number of items ordered and the number of items produced matters. A process that delivers more goods than customers are demanding is not Lean and generates waste. - the number of defects

- the number of items that underwent second-round processing

If, either due to a defect in the process or other reasons, a portion of items ends up processed more than once, this impacts the actual throughput value significantly and needs to be recorded for clarity.

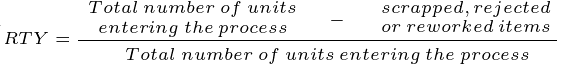

What’s rolled throughput yield?

The rolled throughput yield (RTY) is another Lean Six Sigma metric that measures the probability of the process creating a defect-free item. RTY takes into account any reworked items to provide a clear indication of the actual throughput.

Example If a chair manufacturer works on ten chairs, and during the process, two chairs need repainting due to sub-par paint quality, and the client rejects one other chair, deeming it “wobbly”, it makes their RTY 70%. (10-3)/10 = 0,7.

Using process throughput in a small business

Example

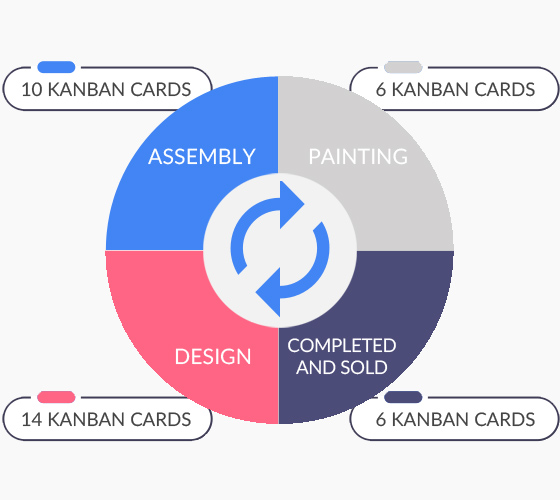

Let’s again consider the chair-making business, which has four departments, producing the following completed items each week.

The team could either consider throughput for each process or analyze the throughput of the entire production. The individual throughput for the Design process would be fourteen, ten for Assembly, six for Painting, and the same for Completed and sold.

Besides applying WIP limits to the Design and Assembly processes, the company could focus on other improvements to increase their volume of six completed chairs a week. Hypothetically, they could move two people from Design to Painting, likely increasing the throughput by two chairs, meaning a 33 % improvement.

If they sell each chair for $100 and produce eight chairs a week, that’s a total of $800. If the company’s operating expenses are $500 a week, the net profit based on throughput is $300 a week.

Aside from giving you general insight into the process profitability, paying attention to process throughput will also make it easier to identify productivity issues and help to keep an even, steady, predictable flow of work. Take a look at why process unevenness is a trait you may want to diminish by reading about Mura.