What is Lean Accounting?

The term Lean accounting describes the financial reporting practices used by a company that embraces Lean thinking: focusing on the value delivered to the client and on waste elimination through better workflow and material management.

Lean accounting means aligning financial management with your company’s Lean strategies. Through that process, not only do the accounting affairs improve but also the economics of your business.

Why use Lean accounting?

The general purpose of accounting is to gather, analyze, and communicate a company’s performance, position, and cash reserves - all types of information used to make decisions on how to manage a business well.

As a result of traditional manufacturing processes making accurate cost measurement challenging, in the 1920s, cost accounting focus started to shift from information for planning to information for control. That led to businesses turning from cost tracking to cost allocation, which slowly became the new norm.

Besides directly synchronizing accounting with a company’s strategy, Lean accounting also reduces wasteful practices from finance management. It limits those processes to a minimum and ensures that financial control does not grow to create an organizational and costly overhead of its own.

A similar waste reduction applies to the Lean understanding of assets. Traditionally, the cost of excess capacity, e.g., more available team members in a service company, extra inventory in manufacturing, was carried over to the customer. Just-in-time, one of the pillars of Lean flipped this on its head, placing focus on only producing what’s needed & when it’s needed and minimizing inventory to almost nothing.

Continuous improvement,

or why you won’t apply Lean accounting in a day?

Taichi Ōno, leader of the Lean approach created at Toyota, realized that the focus of traditional cost accounting was not on creating maximum value to customers and included several processes that would be considered wasteful by customers.

But, you cannot achieve a solution to the problem overnight. First, you need to teach the employees to learn where the value of the process is and how to deliver it to the customers efficiently. They also need to be able to find and remove waste from the process promptly. Only with that can a company gradually establish Lean accounting, marrying the value stream and its financial aspect.

Given that the transformation of your business strategy, preceding any work on accounting methods, will take time, Lean accounting can be challenging for managers hoping to achieve significant results in a short time. A Lean approach to company accounting is a result of continuous improvement, just like all things Lean.

How does Lean accounting work?

1. Value stream-oriented thinking

Lean focuses on optimizing the activities that are part of the value stream and minimizing those that do not add value - from a customer’s perspective. Hence, in Lean accounting, the costs are transferred from a product to a product line, standing to show how efficient a line is. That makes Lean accounting able to measure how effective the engineering or service process is. Most engineers are focused only on their effectiveness in building a high-value product - and that’s understandable. It’s ill-advised for there to be a war between targeting quality or achieving low costs.

But the question of cost vs. quality relation remains. It is down to company strategy and derived from them engineering practices to adjust all efforts to increase value and minimize waste. Only that will allow them to create the means from which the accounting team will accurately calculate costs.

2. More transparent, on-demand reporting

Thanks to the direct relationship between costs and the value stream, expenditure reporting can be captured and processed as quickly as possible. Better yet, ongoing cost amounts can be automated and made available on-demand, as opposed to seasonal bulk financial reporting shared with top-level management only.

The engineers will also derive value from these reports, given how the cost of delivering a product does not tie to just the work and material cost known to them.

Furthermore, thanks to the flow optimization in Lean, costs previously seen as supporting or apportioned can become a part of the production flow. It will allow you to directly measure the supporting costs and subject them to the same rigor driving the entire production line.

3. Delivering what the customers value

Value, as a subjective concept in a customer’s mind, is not equal to costs.

Example If the cost of producing an item is $100 plus a $20 in profit, then the cost to the customer is $120. But if the value to the customer is exactly $120, then - arguably - they leave the transaction without any perceived benefit. They have only materialized their cash value. Hence, we assume that the value to the customer is higher than $120, paying which lets them feel that they’ve made a good deal.

It’s similar to purchasing luxury products - their value to you is higher than their price alone. Included in the concept of value is the sense of achievement you feel when buying the product. Luxury product consumers are happy to spend more than just the material cost of the items due to the subjectivity of value.

Through continuous efforts to learn what your customer values and applying it to the value stream, it’s possible to achieve a process in which this value will steadily increase while waste and cost will drop. In doing so, your company should grow, raise its revenue, and reinforce customer loyalty.

Process execution before accounting

Companies looking to implement Lean financial management first need to adopt Lean ways of operating. Standardizing operations, implementing Kaizen, improving workflows, organizing in work cells all help with adopting Lean thinking and consecutively Lean accounting.

Did you know?

A low-risk method to improve and streamline workflows is adopting Kanban Tool® process boards. Map your flow on the board, and let the team collaborate in an informed and transparent way. Try now!

Once you’ve adopted Lean process management, knowing the direct cost of delivering a product line is, first of all, possible and very useful for planning the organization’s development. Lean companies make it their business to know the value that customers get out of their products. Then, if their processing costs get too high, they can re-engineer the process to keep the market satisfied. Happy customers are the goal for any Lean company. They stand to prove its current state, as well as being a factor in predicting its future.

The requirements for adopting Lean accounting are:

- Identified value streams, with directly tied costing

- Focus on work based on - and adding to - the customer-identified value

- Access to cost reports for all teams involved in value delivery

- Openness to continuous improvements in both the process and accounting.

Example

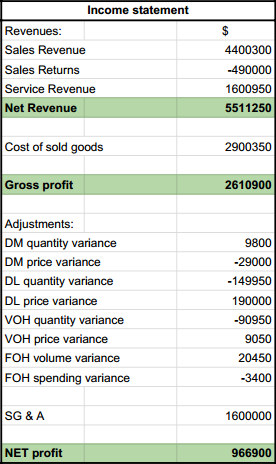

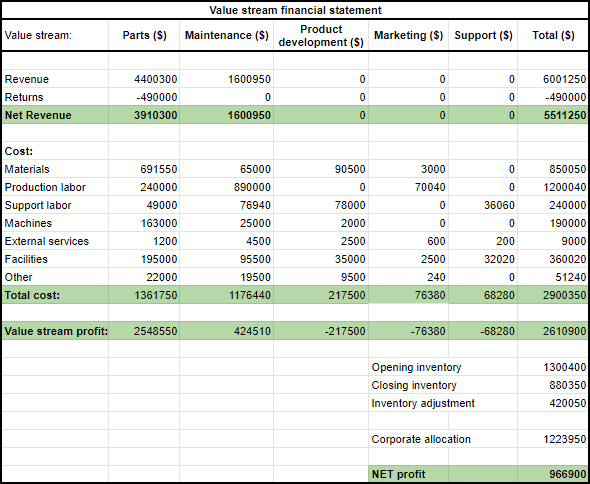

Let’s look at a traditional income statement and a Lean financial statement:

On income statements like the one above, you’ll often see notes and annexures explaining how costing calculations are apportioned, and how the variance is established. That limits the number of people that can understand it. Lean accounting changes this approach, making the report easier to grasp, no matter your role at the company:

On income statements like the one above, you’ll often see notes and annexures explaining how costing calculations are apportioned, and how the variance is established. That limits the number of people that can understand it. Lean accounting changes this approach, making the report easier to grasp, no matter your role at the company:

Lean accounting has to base on your understanding of the value stream with solid knowledge of the production costs. Once you’re well on your Kaizen journey, Lean accounting is likely to become a by-product of your company and operations design.

Key benefits of Lean accounting:

- Less waste in your financial control practices, also thanks to the removal of cost allocation, and more hands-on knowledge of your business costs

- A better understanding of how your financial decisions impact the value stream and the client, and vice versa: broader access to business growth opportunities through the immediate value-finance connection