What is A3 Problem Solving?

A3 problem solving is a Lean approach to reporting issues and presenting ways of addressing them. The simple method, developed by Toyota, bases on documenting a problem, together with its current outcome and a suggested change, on a single sheet of A3 paper (420x297mm), giving it the name. You can use it to make a process change proposal, report on project status, or solve a problem.

A3 takes from the Plan-Do-Check-Act cycle. Though it appears to be a step-by-step process, the method tends to be used iteratively, with the problem and solution sections being cyclically updated.

Taiichi Ōno of Toyota was known for not appreciating reports longer than one page, which helped the proliferation of the A3 approach within the automotive giant’s offices. A3 is similar to the 8D report also widespread in the automotive industry, though typically for complaints management. Furthermore, the ability to quickly discern a problem and understand its solution is innate to Lean values.

Lean emphasizes visualization, with examples in value stream mapping and Kanban’s visual workflows. That made a single-page report presenting what is going on was a welcome addition to a Lean operation.

Through shared use of A3s to solve all problems and plan initiatives, companies can start to operate an A3 system thinking methodology: address difficulties, suggest change, innovate, and curate logical reasoning rooted in the current needs.

Why use the A3 approach to solving problems?

Lean provides a competitive advantage, strategic and operational benefits through its objective to increase the value delivered to the customer and to reduce waste. Engaging in a process that allows the team to find the correct, best solution in the shortest possible time is highly beneficial.

Understandably, some reports and proposals must contain extensive amounts of data, and they have their place in a business environment. But imagine the value and advantage that distilling this information to 1 page has. Consider how much faster decisions can be made based on that. Besides the time savings, the opportunity to use the systematic approach of PDCA supplements the problem-solving skills required to propose accurate solutions.

In preparing for battle I have always found that plans are useless, but planning is indispensable. Dwight Eisenhower

It’s the act of planning that is important, as it spells out all known obstacles, visualizes the action plan, and helps to foresee potential outcomes and issues along the way. While documenting your problem on an A3 piece of paper may or may not yield benefits, the act of implementing A3 thinking is what makes the difference.

The benefits of using A3 thinking are:

- Quicker problem solving

through logical reasoning and application of a step-by-step, visual process. Demanding a root cause identification ensures that difficulties are dealt with, not just temporarily masked. - Easier planning

thanks to the application of objective, critical thinking promoted by the A3’s structure. - Team development

through repeated use of a structural tool to find root causes of problems and their best solutions. The use of one tool across all company levels also promotes cross-department collaboration and knowledge sharing. - Company growth

A3 reports help maintain and keep company knowledge on record, helping to sustain good operating policies and build a strong growth culture rooted in solving a company’s actual problems, not abstract ideas.

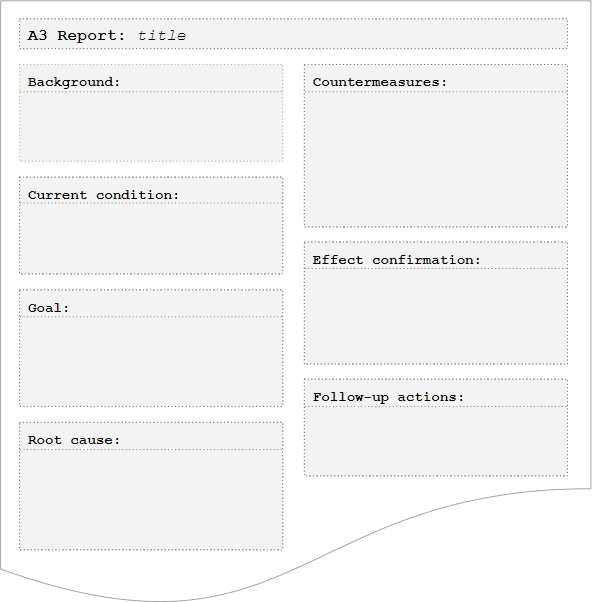

How to create an A3 report?

You can download an A3 report pdf template here.

You can download an A3 report pdf template here.

Step 1: The title

It should focus on the problem you are trying to solve and not the solution you want to convey. Examples of titles are: “Decrease Team Misunderstanding of Task Instructions” or “Reduce Customer Complaints with Product XYZ”.

Step 2: Background

According to the authors of “Understanding A3 Thinking: A Critical Component of Toyota’s PDCA Management System”, one of the main strengths of Toyota is that they place importance on understanding a problem. Rather than rush onto a solution, Toyota takes the time to precisely understand what is going on. The principle of going on a Gemba walk attests to this need to perceive problems first-hand.

The report’s background section conveys important related facts and how the problem aligns with the company’s strategic objectives. Presenting this right there on the page helps minimize the cost that a board of highly paid executives would need to spend looking at a problem, without a guarantee of them understanding it, nor coming up with the right solution. Consider this checklist for your background section:

- Do I know the needs of my report’s audience?

- Have I provided enough context?

- Does what it presents align with the audience’s strategic goals?

- Can the background be explained in 30 seconds?

Step 3: Current condition

A correct definition and a good understanding of the problem is your path to finding the right solution. That makes working on defining the current condition 90 % of the A3 effort.

The objective here is to make sure everyone is aware of the problem, whether the report documents it appropriately, and whether anyone questions the report’s findings. The use of graphs, charts, or other visual aids is beneficial.

Step 4: Goal

Your target - if you hit it, you know that your problem-solving effort has been a success. But you need to know what metrics will measure success and what the definition of success is. An example could be “reducing customer complaints by 15%, as measured by call center statistics”.

Step 5: The root cause

The focus of the root cause section should be to differentiate between facts and opinions regarding a problem’s cause and effect. You can include your findings from 5 Whys exercises, an Ishikawa diagram, or any other result of your RCA efforts. If the root cause is not defined correctly, the problem will likely resurface, causing waste and negating the Lean principles.

Step 6: Countermeasures

The countermeasures should be the corrective actions to take for the root cause of the problem to be resolved. If not possible - without a process overhaul - you can use containment actions instead to stop the issue from directly impacting the customer. It is OK to address complex problems iteratively, along with the values of continuous improvement.

The section may include a table of the problem causes, actions taken, action owners, and the achieved results.

Step 7: Effect confirmation

Since the A3 exercise bases on the PDCA cycle, this section of your report should show the effort you expended to confirm your findings. The proof that you have indeed solved the problem. For example, software engineers include samples that replicate the bugs and verify they are no longer present after a fix.

If the exercise has not taken place yet, i.e., when you’re presenting a plan to gain approval, you should outline what exercises you will conduct to check if the aim is successful.

Step 8: Follow up actions

The final section should include any other actions that you might want to consider. A principle worth adhering to here is the “Shitsuke - sustain” step of the 5S plan. Consider what you should do to ensure the benefits of this exercise are maintained. And could they possibly be translated to other areas of the company?

Conclusion

An A3 problem-solving report will help you deliver information in a way that provides instant value and can quickly reduce waste.

The most important thing to remember is that the act of Lean problem solving is more important than creating an A3 document that may contain no valid data and be simply a tick on some corporate checklist.

The same is true of all Lean methods and tools - their application alone will not make your company Lean. To truly implement Lean principles, your company culture, thinking, and planning all have to transform.

Did you know?

A low-risk, tiny step in attempting a culture change in a company could be getting the teams to collaborate on digital Kanban Tool® boards. Their WIP limits monitoring and process visualization stand a chance to slowly change people’s way of thinking towards more Lean patterns.