What is a SIPOC (COPIS) Diagram?

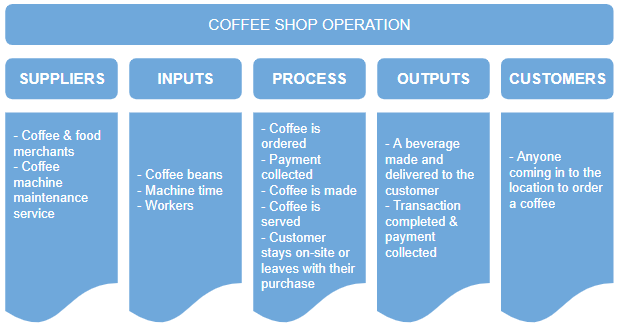

A SIPOC diagram documents an operation’s Suppliers, Inputs, Process, Outputs, and Customers. A list of these elements helps to mark the boundaries of a process at a high level. The diagram provides the decision-makers with crucial information about the entire process without going into too much detail.

SIPOC helps to streamline workflows, identify and solve problems, and remove wasteful activities. It does it through process visualization and limiting the information to only what’s required for management to find the process areas that need improving.

The SIPOC diagram came from the Total Quality Management movement in the 1980s and was adopted by Lean management and Six Sigma practitioners. It usually applies to the “measure” phase of a DMAIC exercise.

When is SIPOC useful?

Given the multitude of factors on which your business success depends, you should take every opportunity to ensure smoother operations and higher customer satisfaction. SIPOC will show you the direct relationship between what you’re asked for by the customers, what you get from suppliers, and how you marry the two in your process. It will help you find answers to questions such as:

- Are your customer requests correctly translated into goods and services?

- Are your suppliers delivering what you need?

- Do you know your customer?

- Is your team taking the shortest route in creating the product?

SIPOC diagrams are also helpful when introducing new team members to a process. And with planning out new business concepts.

Did you know?

The Kanban Tool® application is based on the same process visualization and transparency ideas as SIPOC diagrams. Try it out to share your entire process with the team and suppliers, find and patch any holes in it, and get things done more efficiently!

How to create a SIPOC diagram?

SIPOC maps are easy to make, and that’s their strength! Draw the high-level view of your process alongside the received inputs and produced outputs. Also, list both the customers of these outputs and suppliers of the inputs.

Example

Although the SIPOC form is most common, a good place to start the analysis is, in fact, on the customer end. For that reason, you will sometimes hear of a COPIS diagram relating to the same idea.

Step 1: Customers

Find out who the customer is and what they need. Note that a customer can be anyone for whom the process delivers an output. So there can be internal and external customers. As part of this step, you should also define the level to which the customer can impact your process.

Beginning with the customer aligns with the Lean methods focus, where we think of value in terms of what the customer is willing to pay for. The Lean Six Sigma concept of the voice of the customer is essential here, expressing the needs of the client. Correctly identifying them will help you equip for the customer-specific and validated requirements.

Step 2: Outputs

Outputs are the result of the process, and should strongly respond to customer requirements, ideally, they should be the manifestation of the value, as seen by the customer. They typically are a list of produced goods, delivered services, completed actions, or information gained.

Step 3: Process

It is a list of the high-level steps that make up the process. Capturing the steps in the middle of the SIPOC diagram provides an overview of where the process starts and finishes and what it involves. Make sure you only list the few vital, general steps - no more than 10 - and that you don’t go into too much detail.

Step 4: Inputs

Inputs are provided into the process by the suppliers in the form of materials - be that physical goods or information - that a company needs to function. To make your inputs and the entire SIPOC accurate, make sure to gather all the relevant stakeholders when you draw it up.

Step 5: Suppliers

They are the source of inputs into the process. Given that the diagram is meant to be concise, concentrate only on those suppliers who have a direct impact on the process outputs.

Stay open to improvement opportunities

Keep the satisfaction of your customers in mind and allow the SIPOC creation to trigger questions such as:

- Is there any way we can make this process easier?

- Are we delivering quality to our customers?

- Are we managing our suppliers in the best possible way?

Addressing these questions will help you along on your Lean journey. To learn more about how you can make that journey, please view the articles under Lean Thinking.