What is Hoshin Kanri?

Hoshin Kanri is a Lean approach used for strategic company-wide improvements.

The phrase Hoshin Kanri (方針管理) means policy management and represents the concept of guiding an entire company in an agreed-upon, clear direction. It’s made of three Japanese words: Ho (method), Shin (compass), and Kanri (management or control).

Hoshin Planning, as it’s also called, consists of 7 points setting the direction of improvement initiatives, which unify company organizational strategy.

The origins of the idea trace back to the times of Miyamoto Musashi, a great Samurai teacher of strategy. Hoshin Kanri is also closely connected to Deming’s Plan - Do - Check - Act cycle, as well as to Joseph M. Juran’s teachings about the role of management in quality control methods needed for strategic development.

Why should companies implement Hoshin Kanri?

As with all Lean tools, the aim of implementing Hoshin Kanri is minimizing waste and driving value to the client. It’s easy to observe that if a company runs multiple Kaizen initiatives at once, they may be overlapping and, in some cases, conflicting with each other. While a company like that could achieve some results, they would be far greater if a systematic approach to deploying strategy - Hoshin Kanri - was used.

Not knowing what to say no to, rather than what to say yes to, is a common problem in strategic development. Too many projects lead to staff burnout and generate waste through context switching, resulting in delays and fewer projects completed at the end of the year. Since fighting overproduction with decreased Work in Progress helps to minimize context switching, it will also improve your process throughput.

Hoshin Planning makes it possible to deploy a cascading strategic direction at all levels of a company, from the CEO, right down to a local team leader, also delivering ways to communicate and monitor that direction successfully.

Did you know?

One way to manage and plan improvement initiatives at various execution levels is using the online Kanban Tool® boards. Boards’ access can scale along each project’s range to allow managerial oversight.

Try Kanban Tool® for projects and change initiatives of any scale.

How to use Hoshin Kanri?

There is no better example of a successful implementation of Hoshin Kanri than the Toyota Production System. That said, it will be crucial to keep in mind that the automotive masters have decades of Lean maturity under their belt. Hence, trying to copy them without a preexisting culture would be equivalent to expecting a kid playing in their backyard to perform a triple salchow - the results will not be pleasant. Your journey should start with maturing present working models before you begin emulating Toyota.

Step 1: Strategy: Create the vision

Build a 10-year vision on data from experts and your leadership team experience gathered across all areas and company locations. It will be worth considering any vision statements and strategic goals already maintained and whether they need updating or turning into brand new ones.

Step 2: Tactics: Build short term objectives

Translate the 10-year vision into more concrete, actionable 3 to 5-year plans. Do this through the process of nemawashi: a collaborative approach in which senior and mid-level management discuss the viability of the proposed objectives, making reality-based adjustments where necessary. Typically, at this stage, it pays to distinguish between the objectives valid from an existing client perspective, and form your potential client outlook, separately.

Step 3: Set up detailed, yearly objectives

Next, create annual plans that further break down the 3-5 year strategic objectives to decide how to allocate targets to specific teams and how they should achieve them. This one is a continuous, collaborative back-and-forth process known as catch ball. It ensures that, e.g., national and regional goals are refined while - yes - stretching the team but without creating unrealistic expectations.

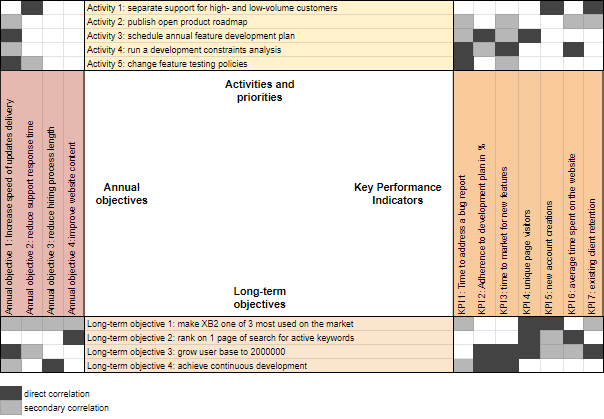

Step 4: Communicate objectives to operations

It’s time to communicate the plans made at step 3 down to the teams, along with KPIs and objectives. These plans are often communicated using a Hoshin Planning matrix or supplemented with project plans, resource demands, value streams, and other artifacts. All goals need translation into measurable metrics at every level of the hierarchy.

Step 5: Execute the objectives methodically

Finally, you execute the yearly plans and objectives, often using the PDCA cycle or Kaizen events based on SCORE: Select, Clarify, Organize, Run, Evaluate. The crucial element is to offer the teams a framework to plan, make, and measure improvements. Failing to do so is likely going to render the objectives unachievable.

Step 6: Review if the objectives are met

Through Gemba and Kaizen the plan needs a review to see how the company is progressing. To schedule any actions for now and to set goals for next year. Do the review at intervals that best match your company size and speed.

Step 7: Analyze objectives for the next year

Using the data gathered during the 12-month experience, you can now determine realistic goals for the year to come.

Remarks on Toyota’s experience

It is important to note that Hoshin Kanri, just like any other Lean tool, is not a silver bullet. The author of “The Toyota Way” book mentions how Toyota never used the Hoshin Planning Matrix, in trust that tools like that could degrade into fancy charts that do not produce any discipline or focus on improvement.

Hoshin Kanri’s key focus at Toyota has been to develop its people and leaders. Rather than being a cost-cutting, quick profit-making tool, Hoshin Planning is a long-term philosophy, focusing on building a process relevant to producing the best results.

The key benefits of using Hoshin Planning

- Unity and understanding of goals across all organizational levels

- Maintained alignment of goals through time, thanks to regular, detailed reviews

- Higher levels of strategic buy-in across all levels

- Easier decision-making process with more empowered employees