What is the Theory of Constraints?

There are different ways to improve process efficiency, but the element that is typically the key driver and - at the same time - the cause of diminished performance is the limitation on a given process step. For instance, you can have 15 software developers writing new features and fixing bugs, but if the team of testers consists of just two members, then it is that two people’s speed and effectiveness that limits the development pace.

Just as a chain is only as strong as its weakest link, your process throughput is only as fast as your slowest production step.

What’s the goal of using the theory of constraints?

The theory of constraints is a methodic approach to focusing on the limiting factor until you reach a flow no longer constrained by the blocker.

It’s common to start with the constraint of the highest impact and work your way down through all the limitations until achieving a leveled and predictable flow. In other words, you’re viewing the process as a complete system and are prioritizing the bottlenecks at play, addressing them in order of importance.

First described in 1984 by Eliyahu M. Goldratt in his novel “The Goal”, the theory of constraints stands strong to this day. It makes it easy to appreciate that an organization’s efficiency is not the sum of individuals’ skills and proficiency but more the outcome of careful cross-departmental planning, work processes synchronization and many series of precise adjustments across all teams.

Theory of constraints application

A few characteristic techniques are used to identify and remove process constraints along with the philosophy of TOC: the Five Focusing Steps, the Thinking Processes, Drum-buffer-rope, and Throughput Accounting. They provide the practical means by which you can answer the following questions:

- What needs to change?

- What does it need to change to?

- How to achieve the change?

With Five Focusing Steps, you identify the bottleneck slowing down the process and pour all available resources into resolving it. After that, you work to synchronize all other steps with this constraint so that the preceding and following production steps are in line with its pace. If that does not resolve the issue, you take additional action to make the constrained step fluid again Finally, you repeat the same process on the next point of constraint in the process.

The Thinking Processes technique allows managers to spot limitations in highly complex systems, also those within the knowledge work/service industry, where constraints are less obvious to identify due to them lacking a physical form. The Thinking Processes identify the root causes of problems by listing their manifestations within the flow - referred to as undesirable effects (UDEs).

Drawing tree diagrams of the UDEs as they are now and how they should be, make it possible to devise actionable tactics to achieve the desired effects in the future.

Within the Thinking Processes techniques, you will come across the following types of diagrams:

- current reality tree (CRT) - present state of a process,

- evaporating cloud tree (EC) - possible ways to solve a problem,

- future reality tree (FRT) - planned state of the process,

- and strategy and actions tree (S&T) - tactics to implement a solution.

The drum-buffer-rope concept ties the production pace to the identified constraint while keeping work in progress and inventory under control. In the system, the limitation is the drum, giving a beat to the pace of the flow; the time within each item must reach every process step is the buffer, and the synchronization of all supporting work with the beat of the drum is the rope.

Throughput Accounting takes a unique approach to accumulated inventory for accounting purposes. Rather than seeing it as potential cash - goods that can be sold, it views inventory items as debt - a sunken value. Another way that throughput accounting departs from the traditional methods is by taking the emphasis away from cutting cost and moving it to improving production throughput - and, hence, the sales flow.

What benefits does TOC bring?

Thanks to the simplicity of the TOC concept, it can be highly effective in both showing the need to make a change in a process or company as a whole, as it is to bringing the change about. The possible outcomes of the theory of constraints application include:

- Structured improvements: rather than guessing or following a theoretical, schematic improvements agenda, managers can build a real-life hierarchy of problems (constraints) to tackle in time, from the most limiting down.

- Saved resources, thanks to precision improvements: putting the effort on the spots where it can have the most impact.

- Simplified problem-solving and quicker sub-performance identification through precise root cause analysis tools.

Theory of constraints vs Lean manufacturing

Both the TOC and Lean are focused on improving productivity and evening the flow of work. However, the approaches that the two philosophies take are quite different. Lean manufacturing is set on eliminating waste from the process, e.g., by cutting costs. The theory of constraints works towards eliminating throughput limitations, e.g., by an increase in production capacity.

That does not mean it’s not beneficial to source from both of them when working towards a more efficient process, and companies will often use both approaches to their process optimization. Sometimes, TOC will work as a high-level decision tool to find which problems to tackle first, while Lean methods will be applied to the improvement processes.

Theory of constraints in project management

Though TOC originated on the manufacturing scene, it’s not uncommon to come across the term in the project management realm of work. In project management, you’re still following a process dependent on several factors with unique limitations.

Bottlenecks typical to project management relate to the project timeline - the schedule and milestone completion; the project’s budget: its value, allocation, sharing, etc.; and the project scope: its precise definition or lack thereof, exceeding or not meeting it.

All of the already mentioned TOC techniques apply to project management too. However, in everyday operations, project managers are more likely to turn to workflow visualization tools with automatic performance metrics than to perform the Five Focusing Steps or Thinking Processes analysis.

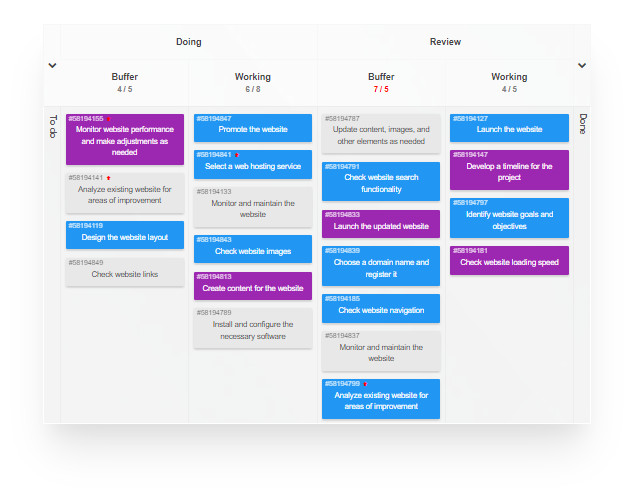

A visual Scrum, Scrumban or Kanban board with WIP limits and automated analytics provides a way to measure the process flow evenness, and spot constrained stages in real-time. Once you’ve identified a bottleneck, you can address it by redirecting resources. When the same constraint keeps occurring daily, it’s a sign that the process needs work and has to be revised to achieve optimal results.

A carefully organized visual workflow management system like this can become a real-life implementation of the drum-buffer-rope system, helping you make the most of the resources you have at your disposal.

Did you know?

Kanban Tool® offers intuitive visual process boards with built-in WIP limits and automatically generated performance analysis. Try the service today to learn which step within your workflow limits you from achieving an even, productive flow.