Bottlenecks & the Five Focusing Steps

Process bottlenecks, or constraints, are the part of a process at which the nature of the flow changes significantly. The name refers to how the speed of pouring a liquid changes when it enters the narrow neck of a bottle.

Bottlenecks usually determine the capacity of a process. The cycle time of the constraint has a direct impact on the entire process’s takt time. While bottlenecks are not a bad thing per se, they can be perceived as the weakest link in the process chain. Process constraints can be reduced with targeted action plans, e.g., the five focusing steps, resulting in improved process throughput.

Why do bottlenecks occur?

Bottlenecks develop simply because in any process - be it a manufacturing line or business process - different activities take different amounts of time, or various stages have an uneven capacity, to unequal numbers of resources.

Uneven flows at different stages can sometimes connect to overproduction. Rather than producing what’s ordered, teams produce what they can within the time and material capacity they have. Instead of tricking the bottleneck to their advantage, the situation is becoming worse. Now the warehouses are full of finished products, demand for which may have changed in the meantime.

Constraints can also be a result of bad planning and poor coordination (see the bullwhip effect).

A bottleneck can also pose a high economic risk, e.g., because it typically runs at 100% capacity, potentially increasing the wear and tear of machines and lacking redundancy. For example, if a plastic molder has to produce a large part, for which there is only one injection molding machine available, this machine itself will become the bottleneck. It means a potential risk of significant idle time for the whole line was the machine to break down.

The reason why constraints are so predominant in the supply chain is a good phenomenon having gone bad. In the 1970s, computerized material planning became successful - those systems (MRP, ERP) had high accuracy, and managers loved them. But sometimes, they were not updated, and teams would trust the machines completely rather than see what was happening on their production floor, which led to an oversupply of material.

Finally, bottlenecks occur also because of batch processing. Machines and workers are sometimes only available at limited times during the day or week. Therefore, to increase efficiency, the raw materials are organized in batches so that the time windows are utilized fully. The problem with this is that it tolerates that an excessive amount of raw material or semi-finished products accumulate in the preceding step, which, in turn, cements the bottleneck and represents muda (waste).

Example

| Steps | Processing time |

|---|---|

| 1 | 2 hrs |

| 2 | 2 hrs |

| 3 | 5 hrs |

| 4 | 1 hrs |

| 5 | 2 hrs |

In a traditional batch-and-queue system, steps 1 and 2 will quickly form an overload of inventory occurring at step 3, making it the bottleneck, with steps 4 and 5 standing idle waiting for step 3 to complete.

Bottlenecks don’t just cause waste through overproduction. They also lead to the steps down the line from them to continuous periods of standing idle.

How to solve bottlenecks with the five focusing steps?

In Lean, we analyze the value stream to reduce waste, and bottlenecks leading to additional loss must deem them unfavorable, correct? Not necessarily. Bottlenecks are like the neighborhood watch of your production line, they often point to problems in the process, but it’s rare for them to be their root cause. Bottlenecks cause slow cycle time - the time it takes you to honor the client requests, but if you understand how to deal with constraints, you can improve your overall process.

One of the thinkers that the Lean movement borrowed from was Eliyahu Goldratt. He introduced a methodology known as the five focusing steps, which worked on improving throughput. It drove down cycle times and increased customer satisfaction. The five steps are introducing positive changes through ..bottlenecks!

Step 1: Identify the bottleneck

Goldratt’s theory of constraints stipulates that if you improve throughput anywhere else other than the point of the bottleneck, you will cause even more loss. Looking at the table above - if we improve the throughput of steps 1 and 2, even more items will pile up in front of step 3. If we improve step 5 throughput, this also will be a waste because it can never reach its new, improved speed. That is because step 3 cannot supply step 5 fast enough.

Leaders going on a Gemba walk should be on the outlook for people or machines who are always busy while others stand idly. It’s typical for the person or apparatus with a pile of work ahead of them to be the bottleneck.

Did you know?

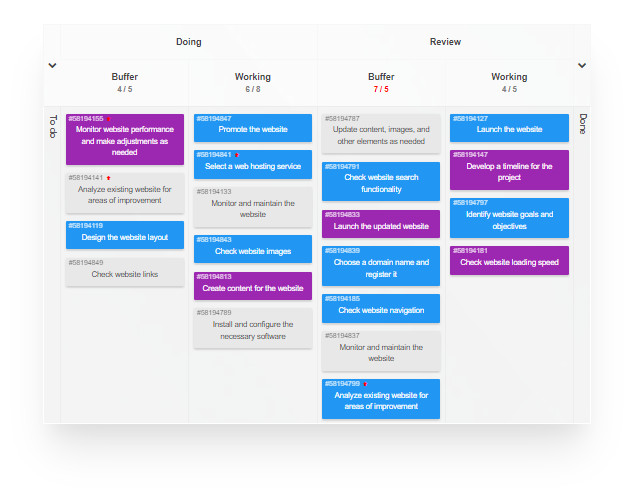

Kanban Tool® visualizes process stages as columns, making bottleneck identification effortless. Try out this simple but brilliant approach, and take advantage of other virtual process board perks, e.g., WIP limits, Process Automation, Time Tracking & Reporting.

Step 2: Exploit/honor the bottleneck

To exploit a bottleneck, we first need to establish whether it is a valid part of the process - be careful that the constraint is not an unnecessary step, i.e., management oversight.

If the bottleneck is a necessary, value-generating part of the process, ensure that it only does the mandatory work. For example, you may have reason to think one of your web developers to be the process’s bottleneck. Yet once you talk to him, you may find out that he had to deal with poor requirements documentation. So besides coding itself, he had to spend extra time chasing down actual requirements. Once you make sure that he has all the information he needs, he can reduce his development time.

Step 3: Subordinate the rest of the processes to the bottleneck

The bottleneck drives the speed of delivery, like a coxswain in a rowing boat. So, steps 1 and 2 should deliver at a pace that will generate a supply of work that the bottleneck can process. The theory of constraints calls this a Drum-buffer-rope approach, wherein a metaphorical rope is tied to the constraint, causing the rest of the supply line to keep up with it. The rope ensures that the line supplies the bottleneck neither too fast nor too slowly, causing it to stand idly. So, the rope takes the role of a buffer, letting the team know when it’s running out of slack.

Lean manufacturing considers process buffers as “good” stock, as they serve to balance out fluctuations in demand between the individual steps. Buffer sizes should be matched precisely to the situation and be as large as necessary and as small as possible at the same time. “Bad” stock is waste in any form resulting from overproduction, unnecessary material stocking, or production surpluses.

Step 4: Elevate the bottleneck

At this stage, you look at how the rest of the production process can help out the bottleneck. For example, maybe steps 4 and 5 in our table can help out in step 3, when it’s overloaded? In Kanban, we call this process swarming - the team tries to relieve the bottleneck by redistributing resources (labor force, in this case) and thus increase output. Or, you can extend the constraint by increasing its capacity: you may need more or faster machines or perhaps greater automation of this step.

Example Going back to the example process table above, if you can double step 3 by, say, getting a second machine run in parallel, you could reduce step 3’s processing time from 5 to 2,5 hours.

Step 5: Restart the process, re-check the bottleneck

The last step in the theory is to ensure that you restart the process at the new speed and observe how things flow through the bottleneck. If needed, start again from the beginning. Once you realize that no matter the improvement you make, the constraint no longer improves the cycle time, it’s no longer necessary to target it. When that happens, it means the relevant bottleneck has moved to another area of your line.

Set up your process to deal with bottlenecks

Bottlenecks are always going to occur, and you need to keep an eye out for them. Organizing your teams or process lines in U-shaped cells can quickly let team members have oversight of the entire line. This way, team members can immediately notice bottlenecks occurring and help out. Having Andons as part of the line can allow team members to stop the line when necessary, or - at the least - it informs them of the current flow.

For teams that don’t share an office, but collaborate on a virtual Kanban board, an effective solution to visualizing and dealing with bottlenecks is to add queuing lanes to the process. Each step of the board should be divided into work waiting, ongoing, and completed, or at least to “doing/done”. This way, if a bottleneck builds up, it will be known within seconds where and why it has developed. Either a step is processing items too slowly or too quickly, or it is overloaded with tickets arriving from a preceding stage.

Additional ways to help resolve bottlenecks

Problem-solving techniques are also helpful when dealing with bottlenecks. Eliyahu Goldratt developed a procedure called the Evaporating Cloud: often, bottlenecks occur because manufacturing processes deal with assumptions that are just not accurate. Evaporating Cloud looks at interdependencies in the process, at what needs changing, and to what ends. The occurrence of bottlenecks often hides the root cause of undesirable effects in production. That is why working with Lean methods is beneficial - the techniques help to ask the right questions to get to the root cause of your process’s bottlenecks.

Using 5S, keeping the process lines clean, and going on Gemba can help with identifying bottlenecks. Also, inspecting the Cumulative Flow diagram lets you check the impact of the improvement initiatives on your bottlenecks and on your process’s cycle time.

Key benefits of addressing and working with process bottlenecks:

- Increased productivity and shorter cycle times, with less stalling and production hiccups

- A standardized way to deal with process congestion & process change

- Contained overproduction - less waste in teams’ time and effort

- A more predictable and stable process throughput - leading to happier teams and satisfied customers

Further reading

- Lean Thinking: Banish Waste and Create Wealth in Your Corporation (BOOK)

- Swarming: A Team-based approach to getting work done

- Theory of Constraints (BOOK)

- Flow in the Office: Implementing and Sustaining Lean Improvements (BOOK)

- The Lean Turnaround: How Business Leaders Use Lean Principles to Create Value and Transform Their Company (BOOK)