What is Lean Project Management?

Lean project management is applying Lean principles, perfected by Toyota, to the discipline of project management. The two fundamental focuses are: delivering value to the customer and minimizing waste, and Lean project managers strive to deliver projects successfully while remaining true to these values.

Lean names three types of waste (the “3M”):

- Muda - time and effort wasted on activities that provide no value to the customer

- Mura - an uneven, inconsistent production process, resulting in time and resource waste

- Muri - overuse of machines or employees.

The application of Lean management practices reduces all kinds of waste, letting the process stand a chance of becoming more efficient, more predictable, value-oriented, profitable, and sustainable.

Traditional vs. Lean project management process

Lean principles have been applied to project management since the publication of “Lean Software Development: An Agile Toolkit” by Mary and Tom Poppendieck in 2003.

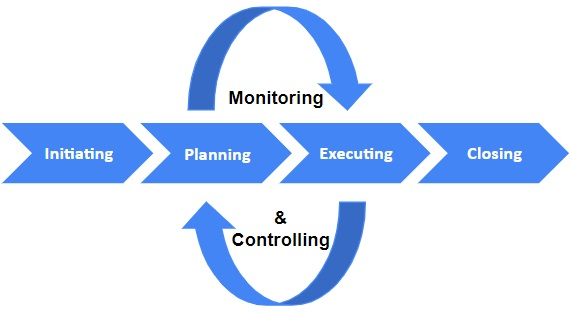

Although Lean PM is nowhere near as established as Lean manufacturing, comparing the two below process cycles will let you quickly appreciate the difference between a traditional or a waterfall model of project management lifecycle and its accepted Lean counterpart.

Lean project management follows Deming’s cycle of change and bases on an iterative kind of process. In traditional project management, many activities are going on at once, with the product delivered at the very end. Lean project management seeks to bring value to customers quickly and continuously, thanks to pulling the deliverables and matching their processing to the current WIP limit.

How does Lean project management work?

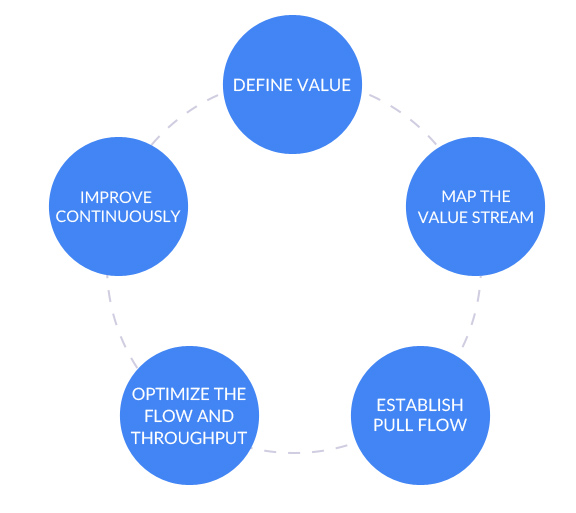

Lean process thinking centers on the needs of the customer. It is the customer who identifies value in your process. Based on that, you map the process value stream and establish the pull-based flow. Throughout the project lifecycle, improvement opportunities are noted and acted upon to ensure constant process growth and optimization.

Step 1: Focus on value - as defined by your customer

Along with Lean objectives, you want the project to deliver value. But, value can only be defined by the customer. Who is the customer? Is it the c-suite, the project sponsor, or the end-user of the product for which the project is developed? Arguably, it can be either:

- The c-suite executive or shareholders, who want the product delivered in a way that is sustainable, controlled, and profitable, or

- The end-user, or customer, who will pay for the service and will be directly impacted by its quality.

Example Let’s say you’re hired for a project to build a shopping site for a health store. Who would the customer be: the store owner who pays for the website or the potential shopper who will buy items from it?

In this context, the project customer is the store owner, whereas the product customer is the person who buys the health items. But no matter who you decide the customer is, we’d argue that providing value to one should also deliver value to the other.

The store owner would not want to work with a substandard site, which could turn customers away. His customers would not want the store to go out of business, which would mean they can’t continually get their goods.

Toyota’s consistently good product quality rewarded with high customer loyalty is a living example of the success of the Lean approach to customer value-oriented process.

Step 2: Visualize the value stream

The above example of two customers and two value streams reveals that there are two processes to consider. The first process would be project management, resulting in delivering the website on time, within budget, and according to the requirements. And the other process would be creating an online health store that would go online upon the project completion.

For both processes, a separate value stream would needs mapping out. Then, one would need to deploy a continuous improvement process to ensure maximum waste reduction and highest value delivery.

It’s common for Lean project managers to aid value stream & workflow visualization with Kanban boards. As they also seek to minimize meetings and status reporting, incorporating Kanban lets anyone see the current project status at any time. Both Kanban and Lean capitalize on the application of Gemba: it’s better to see the status for oneself than to rely on a report that can be fabricated and takes several hours to complete.

Did you know?

Kanban Tool® boards let you visualize the flow and oversee progress in all stages at a glance. Since the service is cloud-based, your team can update their tasks regardless of time and place. Save time and collaborate globally – try it with your team for free!

Step 3: Increase process throughput

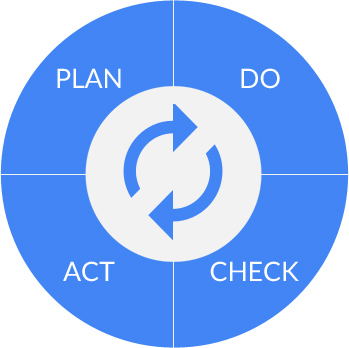

In the same way that a Lean manufacturing process requires keeping tabs on throughput and cycle time values so does Lean project management. Lean project managers seek to get the product into their customer’s hands as quickly as possible. At the end of each Plan, Do, Check, Act cycle, the project team looks at ways to improve speed and reduce waste, enabling them to deliver subsequent features to the client more efficiently.

Step 4: Transform from push to pull services

Traditional manufacturing had orders pushed onto the manufacturer as and when they arrived, forcing them to play catch-up. Lean managers ensure that they have customers pulling the work - signaling their demand. They ensure open communication with the customers, granting them the understanding needed to deliver functionality when it is required. It signifies the need to understand the process takt time, as well as customer behaviors.

Limiting work in progress is an inseparable part of Lean project management. The goal is to provide the client with only the necessary items and to do it fast. It makes Lean projects much shorter than traditional ones, e.g., a year is considered a very long timeframe for a Lean project, with many companies deploying to production daily.

Traditional project buffers allocate extra time to account for risks such as scheduling and cost overruns. Lean project management uses buffer stages only to protect a WIP constraint or a critical chain of the project - the part that takes the longest to complete.

Step 5: Improve continuously

In traditional project management, a Lessons Learned event is conducted as part of project closure. But the trouble with Lessons Learned is that while it can aid future projects, it misses the opportunity for improvement in completed work.

Lean project management seeks continuous improvement. Kaizen Blitz is a dedicated four or five-day event during which relevant stakeholders gather to determine the root cause and a solution to a problem that has arisen within the process - there and then.

Agile vs. Lean project management

Sometimes, the Lean and Agile terms are used interchangeably, which - while harmless - isn’t necessarily correct. Both Lean and Agile describe a way of approaching work in a value-focused way, but they recommend somewhat different ways of achieving it. The scale to which the two approaches can extend in a company is also a strong differentiator here.

Lean originates from manufacturing practices and is more of a systematic approach, an organization-wide method of streamlining how to generate value - see more above.

Agile, with roots in software engineering, also focuses on producing high value fast. But does it through applying short iterations and through attention to perfecting team collaboration.

Our above example, organizing a sprint-based project to build a health store website, was based on Agile software development recommendations. But sitting down with the store owner to discuss the best ways to deliver the best long-term experience to his clients is a different activity. One, that would be best aided with Lean strategies and could require large-scale business skills.

The bottom line is that both Lean and Agile help teams and companies to work better and deliver higher quality to their customers. Therefore it’s common for organizations to take advantage of both methods’ recommendations to achieve the best possible results.

In summary

If you’re following the 5 Lean principles listed above, it means you’re implementing Lean project management, and your customers will likely thank you for your efforts. Happy customers are a distinct mark of a successful company and process.

Through adhering to Lean project management ideas, you can achieve:

- shorter lead times,

- cost reduction across the board,

- improved quality and customer satisfaction,

- better process efficiency and predictability.