Recognize Improvement Opportunities

If your Kanban system is not leading you to improvements, a higher quality of products, business, and outcomes in general, then it should be abandoned. In the words of Masaaki Imai, known as the Father of Kaizen, Kanban should lead to Everyday improvement, everybody improvement and everywhere improvement. It’s an evolutionary process that takes each iteration as a new improvement opportunity.

Standing on the shoulders of giants

When David Anderson considered what principles to integrate into IT Kanban, he looked to industry leaders and change-makers throughout the years. One of those people was Eliyahu M Goldratt, known for his theory of constraints. Change and improvement can be daunting, but one of Kanban’s strengths is that you don’t need to change right away, you start from exactly where you are - change nothing, and simply observe. From observation, you can move on to working with the 5 Focusing Steps.

What are the Five Focusing Steps?

“Five Focusing Steps” does sound a bit like an ancient technique taught by a Zen master to village boys to transform them from weaklings to brilliant heroes. And in many ways, the Five Focusing Steps of the Theory of Constraints can do that for your organization!

Step 1: Identifying the constraint

It requires you to make no changes to your process, just to observe it. Walk the office or production floor and recognize the biggest constraint. If it helps, swap the word “constraint” for “bottleneck” - it’s at the neck of a bottle, where the flow of liquid changes dramatically.

Did you know?

Because Kanban Tool® online project boards suggest dividing your process into stages and placing ongoing tasks in their respective lanes, identifying the bottleneck becomes as easy as noticing which column is the longest and most stagnant. Try it with your team!

Step 2: Exploiting the constraint

Bottlenecks are a process’s speed-change point - they don’t match the capacity of other process stages. Knowing that the speed at which the bottleneck completes work, is the speed of the whole system’s work completion, you need to decide how to best supply the slow stage with materials. It needs to be done at a rate that doesn’t overwhelm (to limit errors), but at the same time, to-do items should be queued up, so that the team is never standing idly.

Step 3: Subordinating everything to the bottleneck

The flow of work, as well as the policies guiding it, must be synchronized with the slowest process step so that further impediments are avoided, or at least minimized.

Step 4: Elevating the constraint

After the workflow has been subordinated to the correctly identified constraint, it should improve. If it does not, it can mean you have adjusted the process to a wrong bottleneck - and need to try again. But if you’ve subordinated everything to the right constraint, and things didn’t improve, then it could mean the problem is elsewhere. To improve the flow through the bottleneck level, you will need to strengthen the stage by investing in better tools/hardware or hiring more people to work there.

Step 5: Observing where another constraint occurs

You need to monitor the process. Typically, another bottleneck will be identified, and you’ll simply need to repeat steps 2 to 5 to resolve it. The Five Focusing Steps model will make it possible to improve the throughput of the system with each iteration.

Eliminating waste

Elimination of waste, or “Muda” in Japanese, is another model for improvement in Kanban. While Kanban works by visualizing your value stream, this model looks at the current activities of the value stream and identifies those that don’t add direct value to the product. This can be a challenging activity, as in some companies, especially the large ones, there are process steps that have been around for so long, that people never question their purpose.

Example Imagine a production facility, where one process step is employee clocking in and clocking out. While this may be crucial for the company tracking costs and paying employees, the customer doesn’t care about this aspect of work. The customer is only interested in receiving the right product on time, hence deems this activity unnecessary.

In Lean, activities that bring no actual value are seen as waste, and as a leader, you need to distinguish between necessary and unnecessary waste. Identifying and reducing activities that are not directly related to producing a quality product, will bring about improvements.

Reducing variation

You may think that Kanban is all about improving speed and throughput and that it will do anything to achieve this, but you would be wrong. The next improvement model draws from the work of W. Edwards Deming, a management consultant and American engineer in the 1950s. Deming was so successful that he was flown to Japan, where local industries incorporated a lot of his thinking into their practices.

Understanding variation is crucial to a business being able to operate smoothly. So, while it may sound great to improve speed throughout the process flow, it needs to be done without creating too much variation. Predictability and a measured and sustained approach should be imperative over the speed of the process. Deming argued that customer trust is gained when a service is reliable and predictable. You should use statistical process control for studying variation and act on the data it provides.

Example In a production company, typically delivering 2 big items and 4 small items a week, the floor manager should set the WIP limit in a way that forbids starting work on a 3rd big product until both the 2 large and 4 small items are finished. The reason being: was the team to keep working on large items before delivering the small ones, and an order for the small ones came, production of the 3rd big item would have to stop mid-way, which causes a new set of problems of its own, like a blocked production line, half-done processes that may not have been allowed to pause for technological reasons and so on. Variation decreases productivity and shrinks process predictability, both of which are hurting your business.

You can easily follow the effect that your variation-reducing efforts have on the process by observing the Lead & Cycle Times, the Cumulative Flow, and measuring the Throughput. Be sure to take note of how long items spend in the idle “waiting” stages, as that’s where most process’ biggest improvement opportunities tend to lie.

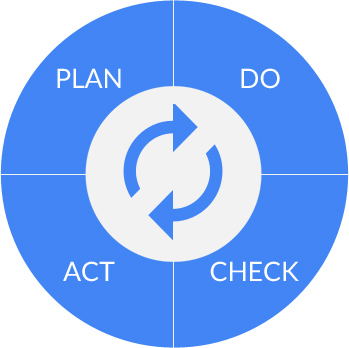

How to use the Deming Cycle?

Aligned with variation-reducing thinking is Deming’s Plan Do Check Act cycle. It also happens to perfectly align with the Kanban notion of continuous improvement. Through its methodical approach to action, the PDCA Cycle helps to keep your process sustainable, along with the changes you propose within it.

Step 1: Plan

Leadership decides what needs to be done to bring about improvement, and then communicates it to the team. Deming stresses that ideally, everyone involved should be included in the improvement process.

Step 2: Do

Here you execute the plan. Perfectly in line with implementing explicit policies and procedures, advised by Kanban practitioners. Take the tangible steps that were discussed while planning, and execute them.

Step 3: Check

Actions get evaluated and the leadership decides if they’ve moved closer to their goals. It ties into Kanban’s flow managing and measuring. Data gathered here will drive the following stage.

Step 4: Act

Not to be confused with “execute”, as that is under the Do stage. Acting refers to evaluating whether the changes made were fruitful, and if not - it means they can be dropped, tweaked, or enhanced. In that case, it means starting the planning stage again.

The Deming Cycle has had a great influence on the practice of Process Improvement Kata at Toyota, where leadership trains employees to understand and resolve their challenges, and then move towards their next target. All of these models: Theory of Constraints, Lean’s elimination of waste, and the Deming Cycle show that achieving continuous improvement is all about the small steps.

Foster an improvement culture through decentralized leadership

While a big portion of the aforementioned methods needs to be applied by leaders, top-down, it’s important to note that you should also breed a culture of progress among the team. Part of that is learning to share and delegate responsibilities to others. People can’t change the processes that they don’t control nor have a full view of! Because Kanban makes the process visible to everyone, team members can get a say in how work is done, and how they think it could be done better, or more easily.