Using Design of Experiments (DOE) in Lean

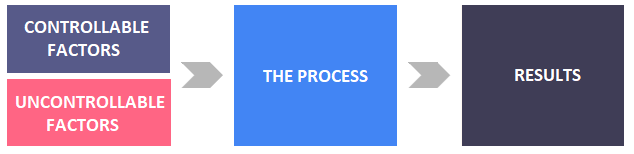

With the Design of Experiments technique, you can statistically determine ways to improve an existing process while limiting the risk of a wasted effort. Experimental Design - as it’s also called, analyzes the relationship between the process factors and process results. In other words, it helps to pinpoint the cause-effect relations within an operation.

Given that continuously improving the process, through waste reduction and an increase in value delivery to the customer, is one of the main goals of Lean, it’s no wonder the DOE method has found use in this realm.

Design of Experiments can help you to:

- define the optimal conditions/parameters for running a process,

- identify current wastes and potential savings in material and energy use,

- compare possible solutions,

- foresee possible effects of the changes that are being considered - for example, during the Analyze phase of DMAIC,

- reduce process variability.

Design of Experiments characteristics

The Design of Experiments tool is prevalent in the scientific domain, where statistics play an indispensable role. But the technique applies to a much broader range of repeatable activities and is often used in Lean Six Sigma practice of process management and optimization.

In the use of Experimental Design, you may come across terms such as:

- Input factors

Both the controllable inputs, e.g., materials, that can change with each new experiment, and uncontrollable inputs to the process, for example, the potentially unpredictable behavior of workers. - Levels

They represent levels of variation in the input factors. For example, a specific time a part spends in a given machine or the applied level of machine setting, such as pressure or force. It’s the degree to which a factor is changed. - Response

It’s the measurable and, importantly, the replicable output of the experimental iteration, so its result.

How to apply the Design of Experiments approach?

Step 1: Define the goal

Make it clear what that the experiment is supposed to measure or analyze. Depending on the kind of question it answers, you will need to reach the answer in different ways. For example, screening design will help you identify the factors with the highest impact when you’re on the lookout for the cause of inefficiency. Meanwhile, the comparative design will pinpoint the most critical factor among the few suspected as causing an undesired result.

Step 2: Choose the factors

List the inputs to the process that you trust to have the highest impact, and please note that less will be more, in this case. You don’t want to look at several factors at once - a couple at a time will be sufficient. As part of this step, it should also be explicit which process response (result) you will be observing.

We also recommend keeping in mind the interactions of the factors at play. Take advantage of DOE making this possible as opposed to the traditional “trial and error” approach. Pinning down an interaction of factors that causes the most damage to process efficiency will be of great value.

Step 3: Adjust the levels and run the experiment

Take note of the level to which the factors are to be modified. If multiple levels are being considered worth testing, which often is the case, you will need to do a separate run for each level, to observe the different results.

It’s good to double-check the data before giving the experiment the go-ahead to avoid mistakes. Commonly, even when not testing several different levels, it will still be required to run the test a few times to replicate the results.

Step 4: Evaluate the results

Measure the outcome and note down the achieved results. Be objective and do this in a quantitive, statistical manner. To do it right, teams typically turn to flowcharts, histograms, and scatter plots. It’s advisable for the person running the experiment to have sufficient statistics knowledge, to facilitate a correct setup and understanding of the responses.

Did you know?

Kanban Tool® boards are fit to help you plan and execute a DOE exercise. Translate the above four steps into a project board, share it with the team, and get on the way to drawing improvement-driving conclusions!

How can your process benefit from the application of Experimental Design?

- The process can be tweaked and optimized based on measurable data, not guesswork, and multiple factors can be experimented with simultaneously.

- It will make it easier to estimate the accurate weight of each element of the process and its impact on the rest of the system.

Thanks to the Design of Experiments, you can improve the process at the exact points where it matters, in turn making your product better, waste and costs lower, and revenue higher.

What’s more, through factor and outputs analysis, DOE won’t only solve critical issues and improve process efficiency. It will also clarify which production factors are the most important and need the most attention.