Pull Systems: The Common Thread Across Lean, Agile, and Kanban

Pull systems sit at the intersection of Lean, Agile, and Kanban, each approaching work execution and planning from a different perspective. Lean, with its roots in manufacturing, focuses on removing waste and maximizing flow efficiency. Agile emphasizes iterative delivery of value, while Kanban centers on visualizing processes and controlling work based on capacity constraints.

Despite these differences, all three converge on a simple yet profound principle: stable, predictable delivery occurs when work moves only when the next stage can handle it. This principle sounds simple, but in practice, it is transformative in eliminating waste and increasing predictability, in result creating sustainable systems.

Two faces of pull: Customer demand and team capacity

Depending on the domain, “pull” takes on slightly different meanings.

In traditional Lean manufacturing, pull is strongly tied with customer demand and the concept of just-in-time. Work or materials are produced only when consumed by a downstream process or an end customer.

Imagine a car assembly line: a part is not made until the next station requests it, or a customer places an order. The signal that authorizes production might be a Kanban card, an empty parts bin, or a new order.

This approach prevents overproduction and keeps inventory low, making it ideal for physical goods. Yet in knowledge work, where demand can be abstract or unpredictable, relying solely on external cues may leave teams idle.

Therefore, in knowledge work, including software development, operations, or creative projects, relying on pull means the team starts new work only when it has the capacity to handle it.

A developer, for example, does not pick up a new feature simply because a manager assigned it; they pull a new task from the backlog only after finishing what they are already working on.

The approach prevents over-commitment, reduces multitasking, and makes workflow predictable; however, it requires balancing with clear prioritization to ensure alignment with customer needs.

Modern Kanban systems elegantly combine these two perspectives. Work advances only when both the necessary capacity exists and the priority is explicitly recognized. This dual condition ensures that teams neither overload themselves nor lose sight of what truly matters. The result is a disciplined, demand- and capacity-aware workflow that can act both efficiently and responsively.

Did you know?

The Kanban Tool® platform helps teams visualize workflow, enforce WIP limits, and manage pull signals effortlessly, making the pull-based system easy to adopt, regardless of scale. If you’re looking to organize a Lean, Agile, or Kanban workflow with minimal friction, it’s an excellent place to start.

Why does pull work?

Based on the above, a well-functioning pull system directly reduces two major sources of waste:

- Overproduction → Excess queues and delays

Pull eliminates bloated queues by preventing work from entering the system prematurely. - Over-commitment → Multitasking and context switching

When WIP is constrained, teams simply cannot overload themselves.

The result is a system with:

- Shorter and more predictable lead times

- Fewer hidden bottlenecks

- Improved throughput relative to capacity

- Clearer signals about where the flow breaks down

Perhaps counterintuitively, pull does not slow down the work; it stabilizes the flow, so that the team can go faster, more consistently.

Pull is the backbone of flow

In Lean systems, pull governs flow: nothing enters a process stage unless downstream capacity signals readiness. It prevents overloading and ensures that work progresses smoothly. Whereas push systems rely on forecasts, individual initiative, or simply on arbitrary pressure, Lean pull creates a rhythm where the system itself determines pace, exposing real constraints and eliminating waste.

Agile benefits from pull similarly: while time-boxed iterations provide structure, they do not inherently control the amount of work in progress. Pull introduces discipline within the iteration, ensuring that teams only commit to what they can handle, creating sustainable, predictable delivery.

Kanban takes pull a step further by making signals explicit and visible: each column, each work-in-progress limit, and each policy acts as a checkpoint that governs the flow of work. An empty slot in a column is not just a suggestion, it is a signal that authorizes work to advance.

The mechanisms behind pull signals

Pull signals translate the principle into practice, indicating exactly when work can move forward, operationalizing the system’s rules.

Whatever the form, the guiding rule is the same: no signal, no work.

Key signal types include:

- Empty slots & WIP openings

A column has an unfilled slot, or a WIP limit is temporarily under its cap. This alone is enough to authorize pulling new work. - Readiness events and policies

Clear “Definition of Ready” conditions ensure an item does not enter a stage prematurely. - Automated cues

Digital systems can send signals automatically, for example, notifying when a downstream item is complete or dependencies are satisfied. - Traditional Kanban cards and bin systems

In manufacturing, cards and empty bins physically travel upstream to signal the need for replenishment.

The impact of pull

When implemented well and adjusted to the unique environment, pull transforms workflow efficiency throughout an organization. Limiting work in progress stabilizes the system, lead times get more predictable, throughput balances within real capacity, and errors decrease because teams are focused rather than scattered. From individual teams to portfolio-level planning, pull ensures that commitments are grounded in reality rather than aspiration: work progresses because the system is ready, not because someone demands it.

Designing an effective pull system

The strength of pull depends on intentional design - each stage of the workflow must be actionable and unambiguous, otherwise the signal will dilute and flow will destabilize. Work-in-progress limits should reflect real capacity, derived from historical throughput, team skills, and task variability. Explicit control policies govern how work moves, who can move it, and how to resolve conflicts - all this will remove ambiguity. Pull also requires careful coordination between upstream and downstream teams. When multiple teams interact, shared limits and defined hand-offs prevent local optimization from undermining overall flow. At the portfolio level, pull signals guide decisions on when to start initiatives, preventing over-commitment across the organization.

Common failure patterns & solutions

| Failure pattern | Symptoms & Outcomes | Fix |

|---|---|---|

| “Soft” WIP limits | Teams violate limits under pressure; managers treat limits as optional. Flow collapses back into push behavior. |

Make WIP limits a strict operational policy. |

| Ambiguous pull criteria | If readiness is subjective, items move forward prematurely, creating defects and unpredictable loads. | Define objective readiness conditions and enforce them. |

| Stage contamination | A column holds mixed states of work, obscuring true capacity. | Split vague stages into clear, actionable states. |

| Local optimization | Teams optimize their own flow while ignoring the upstream/downstream effects. Upstream groups push work to meet their metrics. |

Implement pull across all boundaries, not just within individual teams. |

| Obscured signals | If signals are buried in software or updated too slowly, teams override them. | Make pull signals immediate and unmistakable. |

How to implement pull: A practical path

A successful pull system grows deliberately, not through an abrupt process overhaul. The following staged approach minimizes disruption and improves adoption:

Step 1: Map current flow (Week 1–2)

Understand how work actually moves, visualize the workflow end-to-end, capture ambiguities and delays, and gather historical data on throughput and cycle times.

Deliverables: Visual workflow + list of recurring delays and unclear areas.

Step 2: Identify bottlenecks (Week 2–3)

Analyze cycle times per stage, detect growing or fluctuating queues, and quantify the impact of delay.

Deliverable: Ranked bottleneck report.

Step 3: Set initial WIP limits (Week 3–4)

Derive WIP limits from observed capacity, and communicate them clearly. Protect them from upstream push.

Deliverable: WIP limits posted and acknowledged.

Step 4: Define pull signals (Week 4–5)

Establish readiness criteria per stage, make the signals visible (boards, flags, and notifications), and train the team to recognize them.

Deliverable: Pull signals implemented and visible.

Step 5: Establish stage-level policies (Week 5–6)

Define “Done” and “Ready” for each step, document priority rules and blocking policies, and clarify escalation paths.

Deliverable: Policy guide for all stages.

Step 6: Monitor, adjust, tighten WIP (Weeks 6–12)

Track throughput, lead time, and WIP adherence; spot new bottlenecks, and gradually tighten limits where appropriate.

Deliverable: Performance reports and refined limits.

Step 7: Continuous evolution (Ongoing)

Review the system regularly, propose improvements, and manage inter-team and portfolio-level capacity.

Deliverable: A mature pull system with consistent, predictable flow.

Examples of pull signals in different domains

Software development

Pull determines when designs move to development, when development moves to testing, and when testing can accept new work. The effect: no new features started when testing is at capacity, blocked items surface quickly, and engineers stay focused.

Process steps & pull signals

Backlog / Ideas: All incoming feature requests or tasks. →

→ Ready for Design: Selected items prioritized and scoped. →

→ Design In Progress: Designers are actively working. →

→ Design Review / Validation: Acceptance criteria, UX flows, and API dependencies checked. →

→ Ready for Development: Pull signal: “Definition of Ready” + open dev slot. →

→ Development In Progress: Engineers actively coding. →

→ Code Review / QA Prep: Automated checks run; peer reviews conducted. →

→ Ready for Testing: Pull signal: testing slot available. →

→ Testing / QA: Functional, integration, and automated tests executed. →

→ Done / Released: Feature completed and deployed.

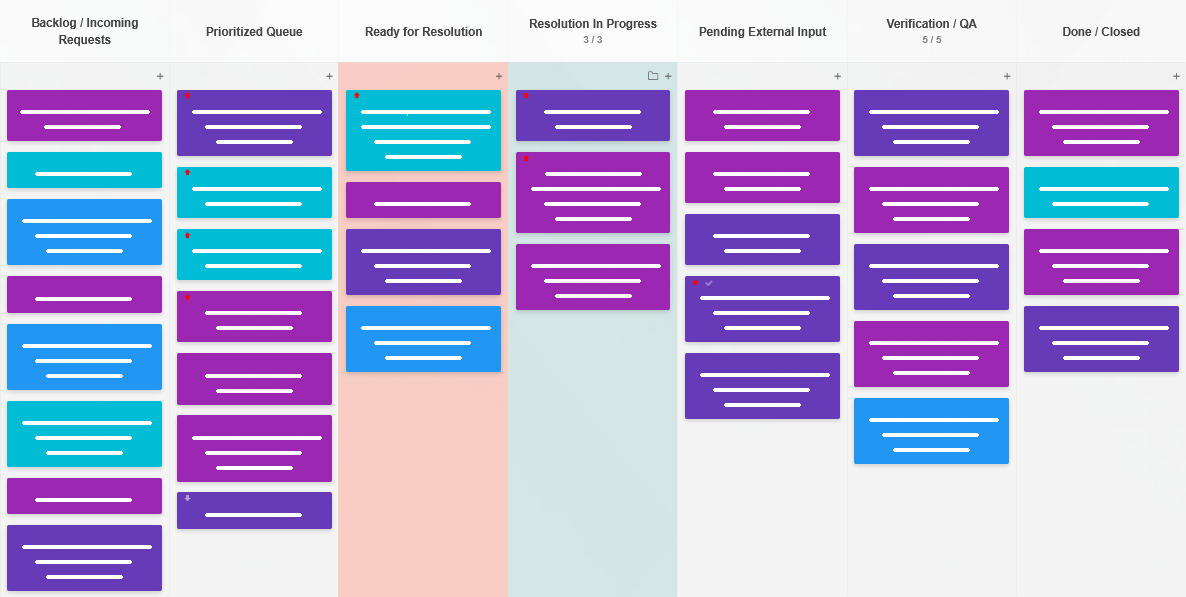

Operational services

Service desks pull tickets into resolution only when capacity exists, which eliminates firefighting and stabilizes response times.

Process steps & pull signals

Backlog / Incoming Requests: All new tickets logged. →

→ Prioritized Queue: Items ordered by urgency, SLA, and priority. →

→ Ready for Resolution: Pull signal: active resolution WIP below limit. →

→ Resolution In Progress: Service reps actively work on tickets. →

→ Pending External Input: Waiting on customer feedback, approvals, or external teams. →

→ Verification / QA: Confirm the ticket is resolved and meets quality standards. →

→ Done / Closed: Ticket fully resolved and documented.

Physical product development

Manufacturing uses classic pull signals: Kanban cards and bin-systems to sync production with consumption, keeping the inventory aligned with actual usage.

Process steps & pull signals

Raw Materials / Inventory: Components ready to be used. →

→ Ready for Production: Pull signal: empty bin detected or kanban card present. →

→ Assembly Stage 1: Initial component assembly. →

→ Assembly Stage 2: Intermediate assembly or sub-component integration. →

→ Final Assembly / QA: Final product build and quality checks. →

→ Finished Goods / Inventory: Product ready for shipment or next stage in supply chain. →

→ Shipped / Delivered: Product has left the factory.

Pull as the stabilizing system backbone

Pull systems transform work from a chaotic sequence of demands into a predictable, self-regulating flow. With pull, Lean workflows gain stability, Agile teams achieve sustainable pace, and Kanban systems operate with clarity and discipline.

The hallmark of a successful pull system is coherence: work moves because the system is ready for it, not because someone forces it. This simple principle creates environments where teams are allowed to focus, and processes flow smoothly, letting the organization deliver with predictability and confidence.

Further reading

- All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production (All About Lean) (BOOK)

- Toyota Production System: Beyond Large-Scale Production (BOOK)

- Implementing a Mixed Model Kanban System: The Lean Replenishment Technique for Pull Production (BOOK)

- Creating Level Pull (BOOK)

- Making Materials Flow: A Lean Material-Handling Guide for Operations, Production-Control, and Engineering Professionals (BOOK)

- Kanban: Successful Evolutionary Change for Your Technology Business (BOOK)