What is Overall Equipment Effectiveness (OEE)?

Overall Equipment Effectiveness (OEE) describes the level to which your process is productive when running. It does not tell you how much your machines and teams can deliver when working at maximum capacity, but what percentage of the ongoing operation is, in fact, effective.

When is OEE used?

The OEE metric applies when identifying the causes of waste in a process, making it possible to fix them, increasing productivity, and stabilizing efficiency levels. It also provides a baseline to which you can compare the process state periodically to gauge if the value you deliver to your customers is increasing or not. Focus on value as seen by the client is of utmost importance in Lean manufacturing, within which you’ll find OEE in use.

Furthermore, an OEE analysis can be your easy first attempt in adopting Lean. Jumping all-in to Lean manufacturing can be daunting and costly, with the Theory of Constraints application being a large undertaking. Meanwhile, you can measure Overall Equipment Effectiveness within a relatively short amount of time and at little cost while still providing valuable information on what needs improving in the process.

Did you know?

Another low-risk way to dip your company’s toes into Lean and Kanban is to adopt an online Kanban Tool® board for project management. It will introduce the concepts of flow, WIP limits, bottlenecks, and throughput management, simply and practically. Try it out!

How to measure OEE?

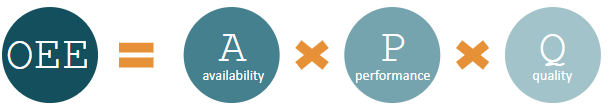

The Overall Equipment Effectiveness measurement bases on the following aspects of a process: availability, performance, and quality.

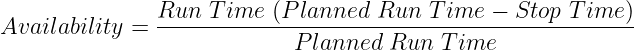

Step 1: Measure the availability of machines to produce goods

How many operating machines do you have? Do not count those out of order due to either scheduled maintenance or breakdowns. To measure your line’s availability, divide the measured run time by the planned run time.

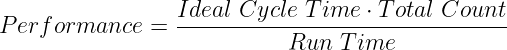

Step 2: Measure the performance rates

Is the throughput even and sustains the desired rate, or are there any small stops, idle cycles, and interruptions slowing it down? To measure the performance rate, you need to relate the recorded run time to the fastest possible time (ideal cycle time) to produce the analyzed quantity of items (total count).

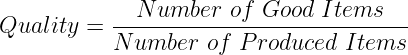

Step 3: Measure the quality of produced goods

What percentage of goods requires to be reworked or gets rejected as defective? Do materials supplied to the process have the ordered properties, or are some driving down the quality? The quality value is, of course, the ratio of the number of non-defective items to all items produced.

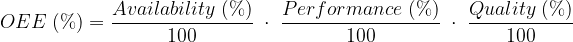

Step 4: Multiply the three values

Each of the above percentage values describes one aspect of your production line’s efficiency. The product of multiplying the percentage values - converted to decimal figures - represents your process total OEE.

What’s a reasonable OEE value to expect?

Were a process to run at 100% OEE, it would mean it’s manufacturing only error-free goods, at the maximum possible speed, with no interruptions. In reality, a 60% OEE is the standard, an 85% OEE is considered outstanding, and production with an OEE below 45% is in serious need of help.

Improving the OEE score

The strength in analyzing production lines OEE is in pinpointing the roots of the problems and the reasons for the highest losses. A common cause will be the lack of standardization, either in the setup of the machines, in material quality, in the operators’ work, or in QA. Varied ways of working and assessing the product will always result in quality inconsistencies, inevitably leading to waste.

It is common for plant managers to install efficiency monitoring screens next to the equipment. These kinds of Andons provide instant access to information about a workstation’s state of operation. Going one step further, using such automated readings can give the manager a live dashboard feed of the current OEE. Having an automated live OEE data across individual production lines is often the goal of companies transforming towards Smart Manufacturing (or, “Industry 4.0”).

A word of caution

It is critical to keep in mind that it’s the losses you identify as part of calculating the OEE that should be the core value of the measurement. Take care to resolve them individually, to truly improve the production, as opposed to becoming fixated on getting the overall OEE number up.

Overall Equipment Effectiveness, while of instantly accessible value, shouldn’t become the sole analysis of the process, nor should it be the manager’s only point of concern. The reason being, that even a relatively high score still does identify weak points and inefficiencies, not addressing which will keep leading to less value delivery to the customer. Managers shifting focus from improving the value levels offered to the client to simply raising the OEE # is a fairly common occurrence - which you should avoid for the good of your customers and your company.

Another reason not to put the OEE on a pedestal is that it doesn’t reflect company health. It does not even touch upon the human aspect or on production costs. Stay vigilant and make sure to use the metric to the benefit of your customers while focusing on continuous improvement. You can achieve it through systematic Total Productive Maintenance practices, so strongly associated with OEE.