Log in

Thank you!

We have sent you an email with details about your accounts.

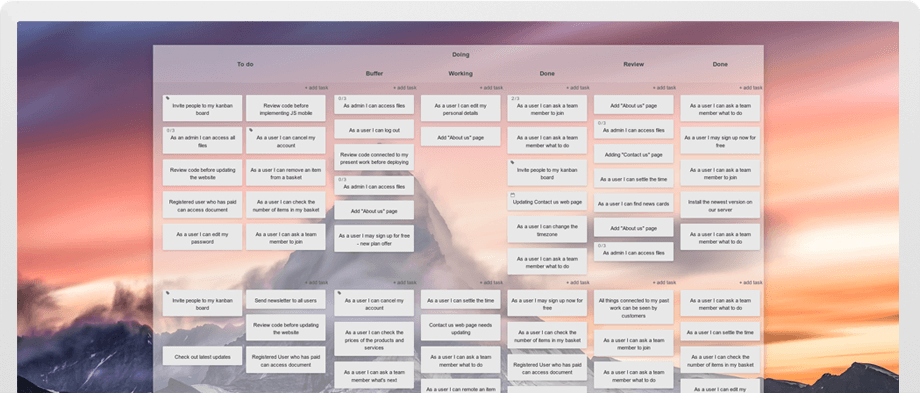

Every account in Kanban Tool has its own web address.

For example, if you signed up to use "acme" domain, your account and login page is available on https://acme.kanbantool.com.

For example, if you signed up to use "acme" domain, your account and login page is available on https://acme.kanbantool.com.

Don't have an account? Sign up »